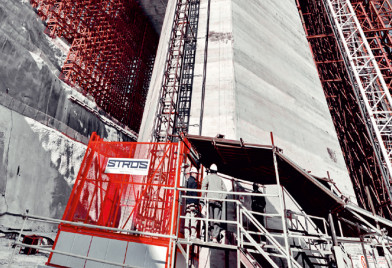

Lifts for mining

When carrying out activities at the mine, it is necessary to use lifting equipment. The lifts presented on our website from the Czech manufacturer Stros meet all the necessary standards and are fully suitable for working in the mine, mining and lifting tools. Cargo and cargo-passenger lifts are designed to lift loads, materials and personnel. They can reliably perform in demanding environments for a long time.

Stros manufactures cantilever lifts and lifts for use in shafts. Their distinctive properties are:

- design that can be installed even in confined spaces;

- two-component coating of parts and mechanisms, which doubles the lifespan of the hoists;

- multi-stage protection system against overturning, sagging, falling;

- automated control of the lift with a joystick, button or keyboard.

Lifting equipment in mines is used for moving and lifting equipment and materials between collapsible levels.